Integrated Dynamics Weekly #3

Microbe touchdown, liquid nitrogen management, Cozad NVC progress.

It’s been a hell of a week.

The subject pretty much covers it all, so let’s dive right in.

We’re greatly indebted to Professor Michael Adams and his team at UGA for helping us get ahold of our microbes. This has been a major struggle for us both time-wise and financially, given that obtaining microbes from a commercial source could’ve cost us about half our total budget, which wouldn’t leave much leeway for more prototyping. We’re wasting no time now that we have them, and have begun cultivating a set of local cultures to let us scale up our testing as fast as possible. Niranjan’s covering this in greater depth below, but what matters is this: we will confirm our model at the lab scale by the end of May.

The discerning reader might remember that we’re working with obligate anaerobes (life which dies when exposed to oxygen), so building affordable equipment that lets us measure gas yield without poisoning our microbes has been our primary engineering goal. Better funded labs have expensive equipment to produce a completely oxygen-free atmosphere, but we’re opting to instead cycle nitrogen through a smaller, closed testing apparatus. So where do we get nitrogen?

Industrial suppliers might charge us up to $250 a month for enough nitrogen to go around, but we’re thinking of something better. UIUC sells liquid nitrogen to its labs for $1.35/liter (roughly 1/30 of a cubic foot), which boils to become around 22 cubic feet of nitrogen gas. Even if we need to refill our four liter dewar ten times a month, we’re still saving $200/month and getting pretty much the same product.

Last but not least, on Thursday we participated in the Cozad New Venture Challenge demo day festivities, met a lot of great people, and were selected to pitch at the final event in Chicago this Wednesday. Not too bad for three months.

—Henry Markarian

Getting our hands dirty

Henry wasn’t lying, it’s game time.

Now that we have our microbes, and after some incredibly careful preparation, we have finally begun our wet testing schedule. The first step began last week, where we started out by creating a master culture. This is a latent source of our specific microbe from which we will take samples to inoculate our tests. We generally should avoid reusing the same microbes on multiple tests to maintain experimental independence, so a separate and constant source of inoculum is mandatory.

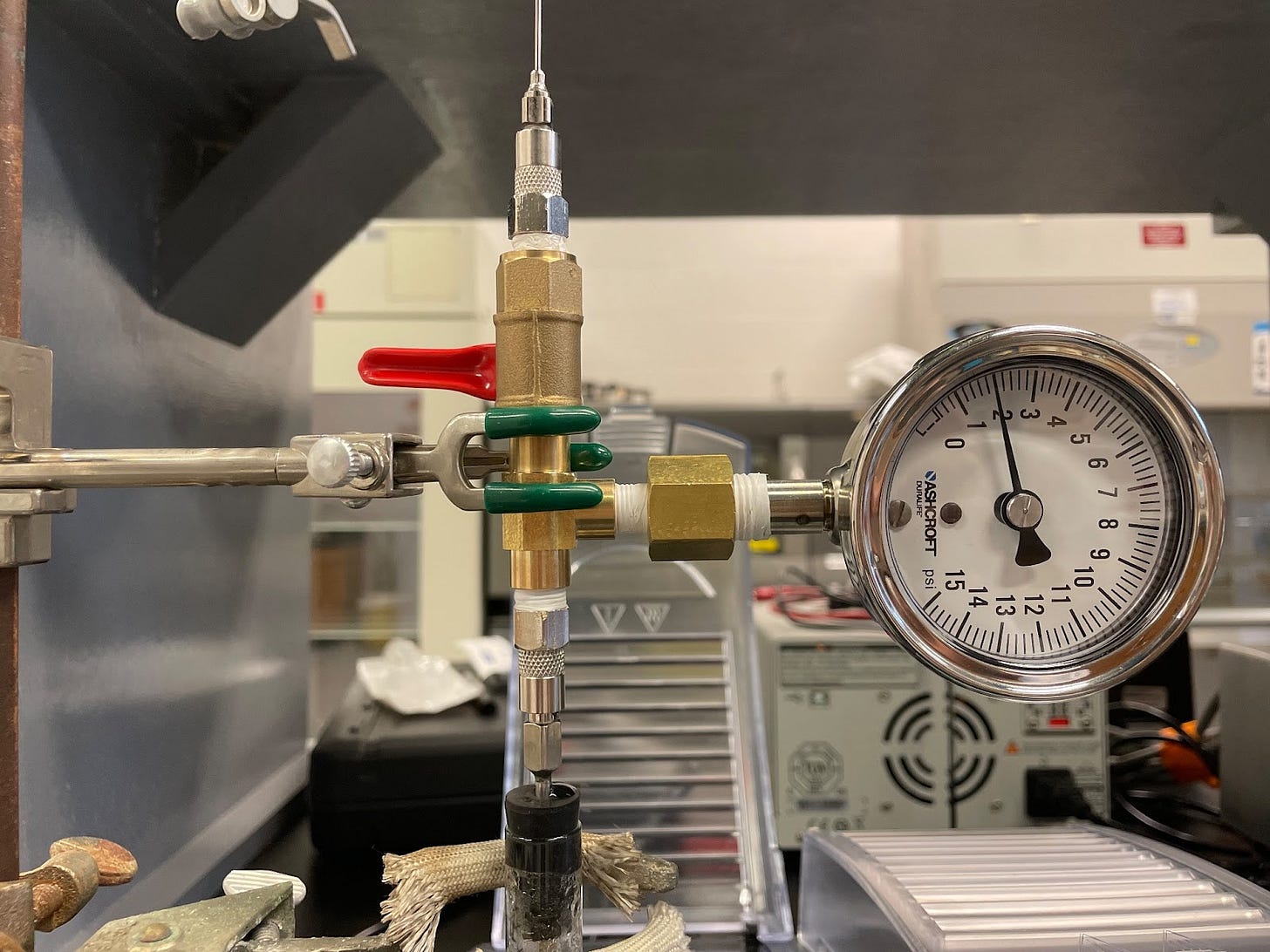

The next step is our lab-scale proof of concept, which is a physical verification of our current yield models. We’ve been working around the clock to improve our gas yield testing workflow, and are proud to announce that we’ve finished our M2 gas apparatus. Henry talked about its benefits last week, which include a greatly reduced internal volume, gas-tight(er) joints, and a new pressure gauge, but also mentioned our struggle with ensuring gas-tightness at the interfaces. The M1 had only a plastic tube friction-fit to a rubber stopper on one end and a few press-fit syringe parts on the other end, and couldn’t sustain more than one PSIG.

Our first fix was a 1/8” to universal ball pump adaptor, but those needles are practically made of dust and broke off before we could do even one pressure test. What stuck was a 1/8” to Luer Lock adaptor at both ends, which lets us screw on gas-tight, sterile syringe needles at both ends.

A side effect of the M2’s better engineering is its cost effectiveness, not only in comparison to other solutions in the market, but also to the M1. The M1, if it were to work, would reduce the cost of an anaerobic testing system below $200 (the gauge itself was $130) per test tube, which is already a whole lot better than the $30k+ it takes to set up a proper anaerobic atmosphere. But, the M2 takes us all the way down to $150 per test tube, and it actually works pretty damn well.

As we keep testing and dive deeper into our results, we’ll be rehashing and reworking our equipment, and we’ll definitely let you all know.

—Niranjan Kulkarni